Hello Engineers!

Do you know the different possible resolutions of the same file?

In one of the previous videos, the one on the 5 most common errors that can occur when exporting an STL file, point 5 was dedicated to file resolution. Before proceeding with the online 3D Printing of your Parts, in this article (and in the video) we go into this subject in more detail, and we do so using the spherical object par excellence: the ball.

TOLERANCE AND ANGULAR DEVIATION

When exporting an STL file, the most important parameter to consider is the Tolerance or Angular Deviation. The unit of this value is expressed in degrees and each software might call it differently, but the concept is always the same. In practice, the lower this value is, the higher the resolution and size of your exported file. Conversely, the higher the value, the lower the resolution and the smaller the file size. In the different softwares you can find preset parameters such as High, Medium, Low: they indicate the resolution obtained after export.

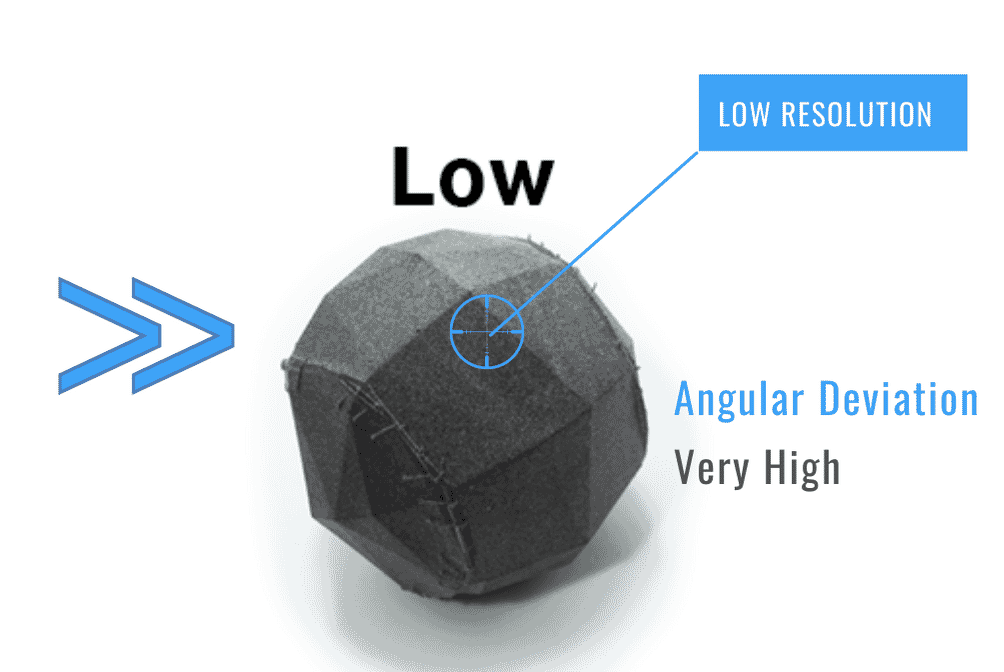

LOW RESOLUTION

The object we have taken into consideration is a 3D printed baseball with a very low STL file resolution. The angular deviation value at the time of export was set to a very high value, which made the object poorly defined and not very similar to the ball it should be.

The various triangles of which it is composed are clearly visible. This way of exporting an STL file can be used to generate, for example, a "low poly" effect, the slightly squared-off digital effect typical of the 1980s.

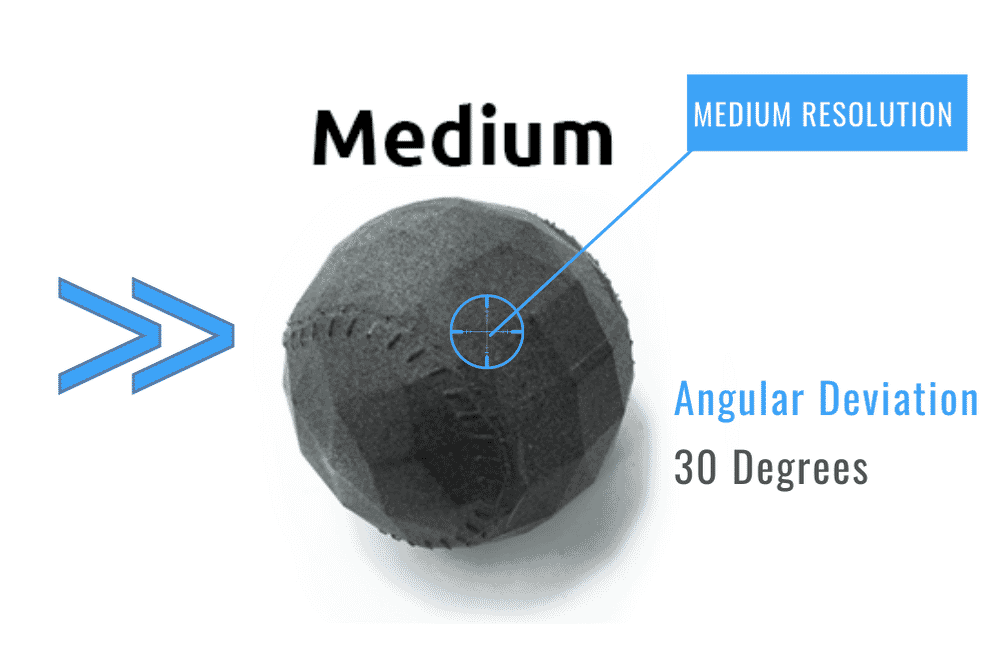

MEDIUM RESOLUTION

The exact same source file, exported at a higher resolution than the previous one, although not sufficient, with an angular value of about 30 degrees, generates a more spherical object, but more like a golf ball than a baseball.

We have used a spherical object for these examples because its sphericity helps us to emphasise the differences that can be generated when exporting a file with different resolutions. If we apply the same resolution value to a parallelepiped, for example, which has perpendicular sides, we would see almost nothing because the surface would be perfectly smooth.

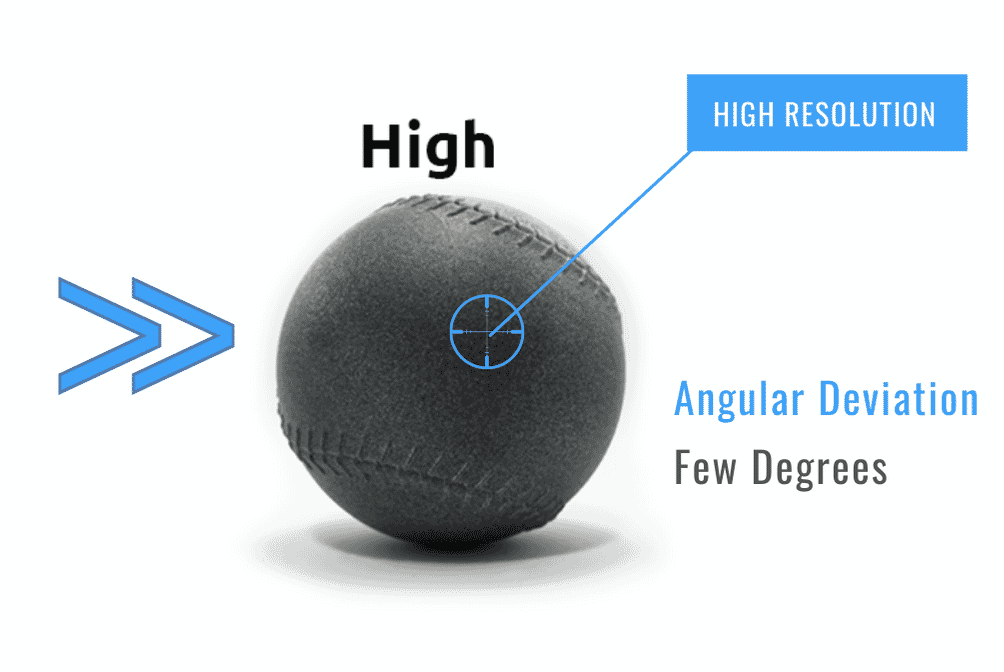

HIGH RESOLUTION

If we use the same STL source file but export it with a tolerance value or angular deviation of a few degrees, the result will finally be our baseball.

We can clearly see that in this case the surface is perfectly spherical and, unlike the other two resolutions, the seams are also well defined. We might think, therefore, that by setting a tolerance value of a few tenths of a degree, i.e. close to zero, we could obtain the best possible result. But no! The file size would be enormous and the printing result would not be far from the "high" resolution.

Apart from making several attempts to find the right compromise, an alternative is to use a STEP file, an interchange file format that all CAD programs support. This format will save you from making choices based on resolution, because it already contains all the mathematical information of the design and allows you to bypass all the problems associated with resolving an STL file.

We at PolyD always recommend that you use a STEP file because, in addition to guaranteeing the best possible printing result, it is also supported by our site.

Happy 3D printing!